If you’re new to the solar industry, go to the Solar 101 Reading list. It has free tools and articles on solar design and installation, sales and marketing, policy, finance and best practices.

According to the Solar Energy Industry Association, the residential market solar market grew by 67% last year. This is great news, but we know from speaking with our readers that the industry is also getting very competitive. We also know that margins can sometimes be an issue and companies are looking for ways to decrease direct costs and overhead. Many industry experts, like Joseph McCabe at Alternative Energy Stocks, at first considered micro-inverters to be for lazy designers, but they are beginning to be viewed as an improvement to centralized inverters saving time in the sales, design and installation process while providing for superior output and reliability. Enphase is a product that has received a lot of business in the past two years, so I decided to have a conversation with Bill Rossi, the Chief Marketing Officer at Enphase, to see how their product could help HeatSpring alumni and readers with their installations.

Q – What’s the story of the product? What’s its history? How was it developed?

A – It’s a typical Silicon Valley story. Enphase was founded in 2006 by two entrepreneurs, MartinFornageandRaghuBelur. They both came from the telecom industry, so they applied the principles they learned in telecom–power electronics and software–and applied them to the solar industry. They came up with the idea to create one inverter per panel, and the micro-inverter was born.

Enhpase didn’t come of the lab, the founders are not academics, and they weren’t from the solar industry. It was a standard entrepreneur story–two engineers looking for an opportunity. Martin was planning on having solar installed on his roof and didn’t understand why solar was designed the way it was or why it had the limitations it did.

Q – Why does Enphase have higher output?

A – We like to use the Christmas light analogy. The output increase fundamentally has to do with the fact that we’re doing the conversation on a per-panel basis. With centralized string inverters, the panels are connected in series in a string, while the Enphase inverters are all connected in parallel. With centralized string inverters, if any one of the panels in a series is not operating up to specification due to shading, mismatch, or dust and debris, the output from the whole array is decreased. However, with Enphase inverters, only the panel being impacted affect the performance (insert image from website).

Editors note: Remembering the design derating process. Your voltage losses for module mis-match, shading, and voltage drop for long DC runs will be significantly less. Also, not having to do these calculations will save you time in the design process

Q – Can Enphase inverters be used on 120/208 or 277/440 three phase systems or only on 120/240, single phase systems?

A – Today, the micro-inverter is only available for single phase systems. We are planning on having a three phase system for the future that can also be used on larger commercial projects in the next generation of the product.

Q – Let’s say you do a site visit and there is enough room for 15, Sharp 210s on the roof. Can you walk me through how the design process is a little different with Enphase than from a central inverter?

A – With a centralized system, you must do all of your string design calculations, selecting the inverter and specifying disconnections. All of the time, you’re calculating for the worst-case scenario (Editors note: both with Voc so you don’t fry and inverter and also with wire guages to make sure you can carry the needed amperage). You need to make sure that your panels will never, under any circumstance, damage the inverter with some fairly complex calculations. Also, if there are two different pitches for the roof, you need to figure out how to utilize two different inverters, because a mismatch in power production will decrease output. In this case, the inverter won’t be able to find a suitable MPPT range.

The beauty of micro-inverters is that they don’t require any design related to DC-AC power conversion. You’re simply determining how much roof area you have where you can potentially fit panels. Our installers are telling us that they save about 4 to 5 hours of design time on each system.

Editors note: Remember, you will still need to make your production corrections for roof azimuth and roof shading. Also, shading still does matter, just a lot less. You’ll also still need to interconnect the panels with the existing service so will have the same constraints as a central inverter because you will be feeding power back into the bus. And this?

Q – What is the process for interconnecting the AC power into the service?

A – Each micro-inverter has a maximum number of inverters you can connect together into what we call a branch. Each branch line is then tied directly into a standard fuse inside the panel, and it’s all AC wiring so you can used standard components. The micro-inverter itself will tell you the size of the fuse that it must be connected with. All of the inverters, and DC combination boxes, are eliminated. However, you may still need to have various disconnects, depending on the code in the town where you are located.

Q – So, if everything you say is true about production and design savings, why does anyone ever use a centralized inverter? Is it habit or are Enhpase systems more expensive?

A – The challenge in residential is that there are always customers who want solar but are just looking for the cheapest solution in terms of upfront cost. Our value proposition for the homeowner is that our product will be cheaper over the life of the system, because it will generate more energy for you at only a slightly higher initial cost. For the installer, it’s all about easier design and faster installations. Some customers simply don’t care about lifetime cost of the energy; they just want the cheapest system that they can install. This is when the string inverter is often used. A lot of our installers will present both scenarios and allow the customer decide.

In the market right now, there are companies offering very inexpensive leasing products where you can get solar for $0 down. Companies are also very interested in lower upfront installation costs. They almost dictate to installers to have lower upfront costs because their financial models are using 5-7 year time periods.

Q – Do you think it’s possible for micro-inverters to be cheaper per watt than centralized inverters any time soon, or is physics in the way?

A – I do believe it’s possible because since the technology is built on semi-conductors, it benefits greatly from Moore’s law. I do believe that over time, they will be on-par with centralized inverts. It probably won’t be this year or next year, but in the near future, I think it will be on-par for residential systems.

Q – Do you notice that when you use Enphase for larger single phase systems, around 10kw-20kw, in small commercial or large residential projects, that the increased down time and higher production make Enphase more attractive?

A – In the larger systems, upfront costs are less of a concern than for a typical homeowner, and they are definitely evaluating the cost over the life of the system. In these cases of larger commercial systems that are 208 or 240 voltage single phase, which is what we support today, we’re definitely cost competitive with centralized inverters. Our sweet spot is between 20kW and 30kW. When you start to get to 100kW and above, you tend to find central inverters that are designed right at that sweet spot instead. They tend to be cheaper on a dollar per watt basis above this measure.

I think that as our technology evolves and the cost per watt decreases, you’ll start to see more penetration into larger commercial systems, especially when you look at installation costs as well. Imagine getting a panel with the inverter already on it–you’ll save plenty of time.

Q – Small increments become magnified on larger projects, so a 10% faster installation time is huge. But reliability must also be a factor, right? If Enphase is more reliable and has a significantly lower down time on a large project, doesn’t that make it more attractive? This can be amplified further in SREC markets where the economics are driven by production. If you have a 1MW system down for a day, that is a lot of money.

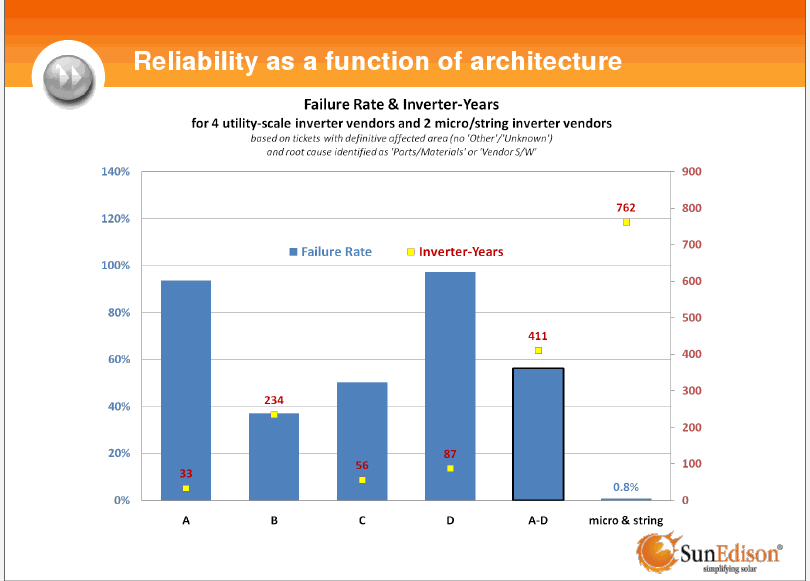

This is a great point. I was at a conference last month, and Sun Edison made a presentation with some data comparing their projects with central inverters versus Enphase inverters over the past 2 years. They were looking at the failure rate, and they found that 98% of the central inverters had at least one “failure” where only .8 % of Enphase inverters had the same problem. This alone will save installers a significant amount of time, money and piece of mind knowing that they won’t need to return to a job.

The following image is from the Sun Edison presentation and shows the reliability of micro-inverters compared to central inverters.

Q – From a contractor’s perspective, what is your best customer and do you vet them? How do you distribute the product?

A – We go through distribution channels. We don’t vet installers. We let our distribution partners do this, and they do a pretty good job. We invest a lot in training. We’ve trained over 3,000 installers face to face. We don’t have any certification process. We offer installers training, and we have a great support team that can help new installers work through any problems.

HeatSpring’s Take:

AC Modules are gaining ground and getting more popular. As module costs have decreased, companies are striving to figure out how to make solar more and more attractive, either by increasing solar output or decreasing installation costs. To see how the AC module does both at the same time, see WestinghouseSolar as an example. From designing and installing systems, it’s easy to see how Enphase inverters can easily save you time in the design process and installation. The huge negative is that you cannot use it with three phases systems, but the growth of the residential market still means there is a huge space in the market for the technology. Also, shop around. There are other micro-inverters on the market. Enecsys is a mirco-inverter companies based on the UK that has received some funding, has solid sales and is going to be expanding into the US as Enphase is headed to Europe.

I am interested in combining a Solar Electric system with the Solar Thermal system in Toronto, Canada.

Could you e-mail me some advice. I would appreciate any help/comments/etc.

Eskay,

The only way the systems will directly interact is if you run the solar thermal pump package on a DC system with a small pv panel. Otherwise, they’re be two completing different systems and will just share some space on the roof.

What specific questions do you have?

Chris