Module prices have been drastically dropping. The result is that companies are increasingly focused on using software to decrease business overhead but there has also been a huge focus on driving down Balance of System (BOS) costs, namely racking. This is the reason we spoke with Lumeta Solar to learn about their great BIPV solution. But we’re also interested in looking at some tradition racking because Lumeta Panels are not suitable for all locations.

Sollega has been developing a very fast racking system used on flat roof so I reached out to Elie Rothschild the CEO of Sollega to get his thoughts on developments in the racking industry. Full transparency, Sollega did not pay us for the review, I did it because I believe that they have an interesting product that can have benefits over traditional racking. If you’d like more information on the product, please fill out the form at the bottom of the article.

Q- What was the story of the product?

A- After the initial idea, we created the first prototype for InstaRack—no projects were built with it, but we brought it to Solar Power International in 2009. The response was positive, so we went back to the drawing board and incorporated a lot of feedback from SPI and the roofing industry. We see the racking as the marriage of solar and the roof industry, so we need to meet the needs of the roofing industry as well as the needs of the solar industry. We worked pretty tirelessly with a number of roofing professionals to make sure we have proper drainage and to make sure our stands are as roof-friendly as possible. One of the benefits of using HPDE is that it’s completely inert, so we don’t have any issues with chemical interference with the roofing membrane. Also, we don’t have any issues with ice or water damming and we removed all of the point-loading issues. It was very important for us to work directly with the roofing industry to make sure that our product fit their needs.

Q- Before the product was created, what were you using?

A- I’m a licensed solar contractor. I’ve been in the solar industry in North California for over ten years and Sollega spun out of Sustainable Energy Partners (SEP). We (SEP) developed solar energy projects and we still do but to a smaller extent. In the past, we used what is today our competitors products, and it posed a lot of challenges. There was a lot of assembly and complicated parts. The inspiration actually came from seeing a couple water walls on a location construction site. Each “wall” is made from HDPE, or high density polyethylene. The use of HPDE gave me the idea, so we went back to the office and talked with the team. After many iterations, we came up with design one. Basically, we had a lot of experience as an installer, and we wanted to create a product that we wanted to use. A product that was easier to install and more flexible, with less moving parts and was roof-friendly.

Q- How long did it take to go from idea to prototype?

A- From idea to prototype, it took about 1.5 years. To bring InstaRack to the market, it took, in total, two years after all necessary testing, including:

- Wind tunnel testing (barrier layer)

- CFD (computational fluid dynamics) tests

- Deconstructing testing

- Grounding testing

Q- Attaching panels and grounding are a bottleneck with most racking. How do you address it?

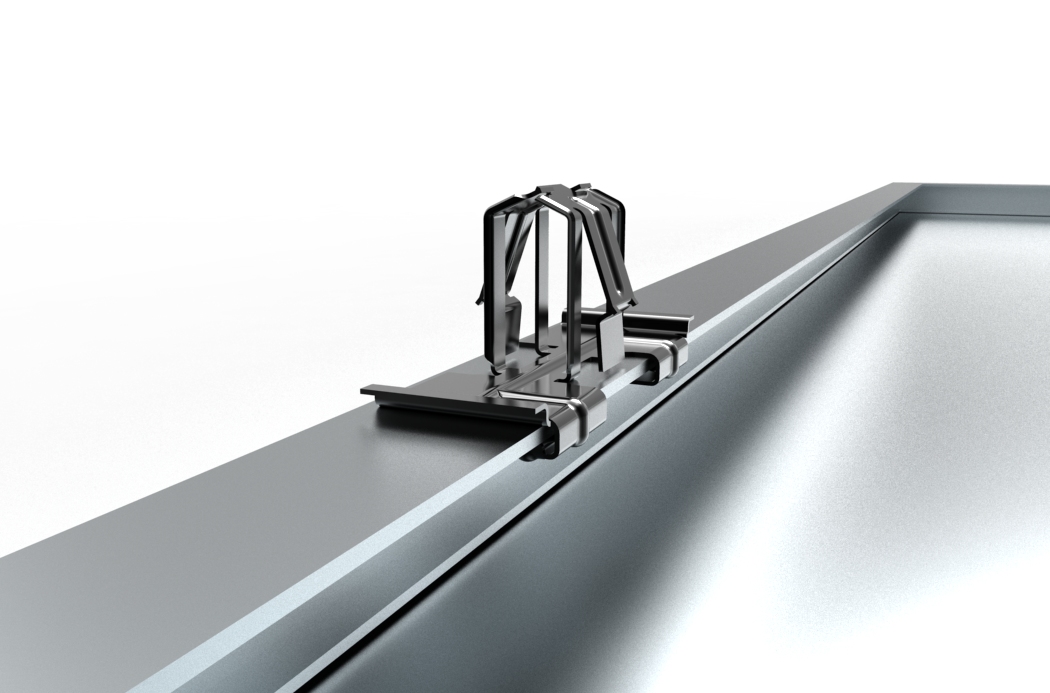

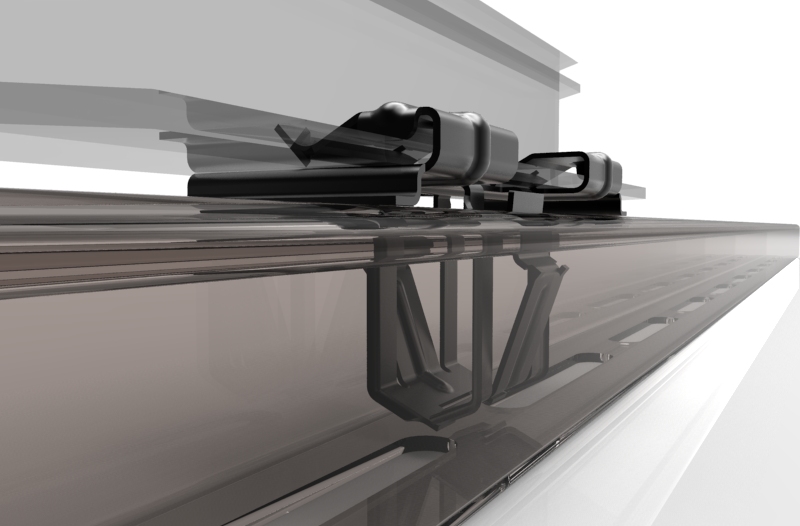

A- InstaRack has an integrated grounding solution. All the panels are grounded to the strut, so you only need to ground each row, instead of each panel individually. Our new QuickSnap technology will allow you to attach panels very, very quickly to the strut. The QuickSnap clip will automatically ground to the strut as well. The technology is in testing but will be available soon.

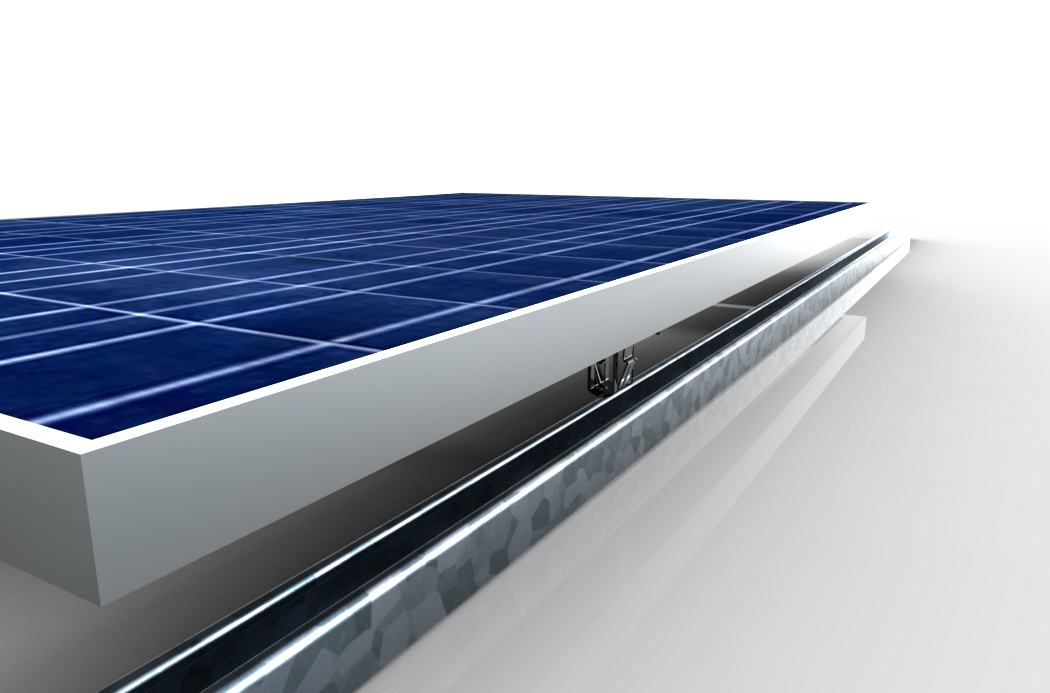

Right now we have two attachment methods. We have the pre-panel and the top mount.

If we have a large project, or the client wants to reduce the amount of traffic on the roof, assemble a lot off the roof or save money on labor, we can attach the panels to the strut two at a time. The two panels are assembled off of the roof and grounded to the strut. On the roof, they only need to lay out the stands, bring up the ballast, and attach the panels two at a time and attach them to the stands. The grounding is still done through the strut, so they only need to ground each row.

The second process is the top mount. For the top mount the process is simple. First we install the strut, then the hinge plates are mounted to the leading edge of the modules and fastened to the strut. We currently use standard inter-module and end clamps for top rail attachment.

Q- I can see that InstaRack can save a lot of money and time in terms of attachment (because you can do it off-site) and grounding (because you can ground each row). Can you discuss QuickSnap?

A- QuickSnap is something we’re developing with ARaymondTinnerman, one of the largest attachment manufacturers in the world. It’s currently going through UL testing. It is a universal clip that slides onto the bottom lip of the module. It bites onto the module and then snaps securely into the strut. It’s very quick and very easy. We’re going through testing right now, but the goal will be that the QuickSnap also grounds the panel to the strut. The other benefit is that is requires a special tool to remove, which provides additional security from theft. We think the QuickSnap may actually get rid of pre-assembling. Our system right now is very fast–when the QuickSnap is released, we’ll have the quickest racking system available.

Here are some great shots of the QuickSnap product and the steps it will need to be installed.

Q- Does the InstaRack allow for multiple tilt angles and row spacing for proper design?

A- The InstaRack comes in a 10-degree and a 15-degree tilt angle, which are the most popular angles in the US. Flexible inter-row spacing is built into the design, so you can build in the spacing to meet the need of the project.

Q- What is the typical size of installations?

A- The typical size of projects are 100kw to 200kw, but we’ve done projects with many different sizes, from 50kw to 1mw. Next week, one of our clients will start a project for almost 700kw in southern California.

Q- Who is your best customer? How do they get product from you? Is there a vetting process?

A- Our customers are all integrators, installers and developers with projects on commercial flat roof spaces. One of our account managers will talk with prospective customers to specify the need and the options for a project.

Predominately we sell direct to insure quality of service. We have a few distributors for niche markets, but what we want is to make sure that value is added when our product is purchased in terms of design assistance.

We are developing an online design tool so a layout and proposal will be able to be generated and printed out by our clients. It would save us time, and it will save the installer time because they don’t need to wait on us to get their designs completed.

Q- To summarize, what are the main benefits and features of the product versus other racking products? To a contractor, what will make your racking standout?

A- There are four main benefits to using a product that a contractor would look at:

- Great interaction with the roof. The HPDE is completely inert, so there will be no chemical interaction with the roof. Also the stands are designed so that there will be no drainage, water damage, or point loading issues.

- The connection of the modules to the frame can be done off-site, and with the QuickSnap, done extremely fast on-site. Grounding is done on a row-by-row basis, not panel to panel, saving a significant amount of time.

- We use readily available parts so it’s cheaper, and you’re not dependent on us. The only propriety technology we use is the stands, hinge plates and QuickSnap.

- Our shipping costs are cheaper due to the lightweight nature of the product.

Q- What support do you provide?

A- We provide the following:

– Installation training for companies

– Easy to understand installation manual

– Customer service for immediate assistance

– PV-system design layout

– Ballast and wind calculations

– Engineering data and spec sheets

HeatSprings Take:

Here’s the reality, all the racking on the market works, just like solar modules. They all work, it’s simply a matter of preference. I can say from experience the amount of time saved on attaching modules with the QuickSnap and being able to ground each row will be a huge time saving. On a large job, this could easily add up to be a couple days work. If Sollega can also create an online tool used for creating racking designs this will further streamline your sales process. Also, the roofing industry is becoming more active and stringent with warranty issues of solar being placed roofs. I like Sollega’s use of HPDE and the close relationships they have with roof manufactures. This is a key element you’ll want to address in your projects to mitigate risk.

In the end, it comes down to preference. A lot of the savings involved with Sollega does not seem to come from the parts themselves but how they are utilized. It all comes down to the quality of your crew and how knowledgable they are about the product. If you’re getting into the industry and you’re going to be doing a lot of flat roofs, I’d give Sollega a try.

If you’re interested in getting more information about Sollega’s product, please let us know.

[…] renewable energy more badass, and by badass, I mean profitable. Whether it’s AC modules, faster solar racking, or PV modules that don’t require racking or grounding, huge projects that are pushing an […]